PRODUCTS - End Forming Systems

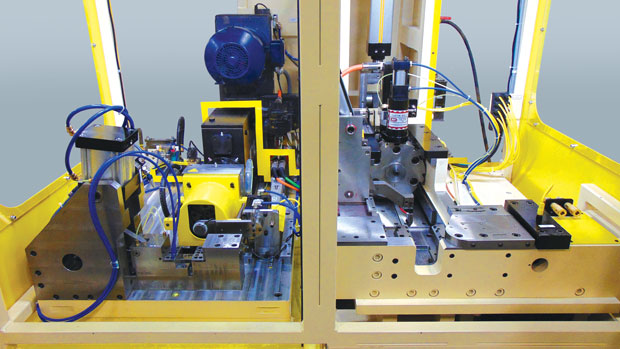

Model M10-E Series Multi-Platform Tube End Forming System

The Manchester model M10-E series is an electrically controlled tube end forming/roll forming machine with tube capacity up to 3/4” (19mm) diameter.

The end forming station is an M71-E-6 or M71-E-3 model ram. The M71-E-6 has a servo driven, six position rotary shuttle and the M71-E-3 has a pneumatically driven, three position shuttle. These are easily programmed through the machines HMI. The ram is servo driven through a mechanical linkage system and also allows for independent stroke speed adjustment. This station also accepts the same tooling at the M71-H & M71-E models.

The roll forming station uses the 24020 model 5HP variable speed ball screw unit. The spinning head speed is adjustable from 300 – 1,200 R.P.M. This station also accepts the same tooling as the hydraulic 24008-HS model.

Both stations can be operated either consecutively or simultaneously by an operator or integrated automation. And the clamp system for both stations is a pneumatic linkage system.

Standard Equipment

Machine Weight is Approximately: 6,800 lbs.

- Air Required: 95 PSI & 4-5 CFM

- Electrical Required: Customer Specifications

- Servo Flag Stops

- Part Present Sensors

- Recipe Storage through HMI

- 12 Month Warranty

End Forming Station

- Tube O.D. Capacity: 1.5" (38mm)

- Cycle Time: 2.0 to 9.2 seconds*

- Ram System: Servo Driven Toggle with 6" of stroke

- Clamp System: Pneumatically Driven Toggle with 8” Bore Cylinder

- Available in 6 stroke rotary or 3 stroke swing

Roll Forming Station

- Tube O.D. Capacity: .75" (19mm)

- Cycle Time: 4.3 seconds*

- Main Drive Unit: 5HP variable speed drive with Ball Screw Unit

- Recirculating System: 3/4" HP Graymills Pump

- Clamp Cylinder: 4" Bore with Toggle System

*Cycle time depends on end form & machine parameters

Valuable Options

- Autoload & Unload Systems

- Custom Cycle Start Initiators

- Custom Painting

- C.E. Certification